Roller destoning machine

This machine has the purpose of destoning various kinds of stone fruit, such as peaches, apricots, plums and cherries, producing a destoned mash.

The fruit is pushed by a guillotine between two rollers rotating towars each other, rubber surface roller and the toothed-disk roller. Fruit gets crushed between the rollers and the stone gets pushed into the rubber, by the toothed-disk roller. The rubber will push the fruit pulp between the toothed disks and will get stuck. The stone will fall off the rollers, a special sorting blade guarantees the separation of the stone from the pulp. The squashed pulp in the toothed disks is scraped by means of comb scraper. Stones, after separation, need to be passed in the stone cleaner, for a complete pulp separation from the stones.

The distance between rollers is regulated, depending on the fruit and its stone size. The teethed disk thickness and spacing vary, according the type of fruit being destoned.

Stainless steel construction and mounted on pivoting wheels. Feeding roller for even feeding of the fruit into the destoning part of the machine. Pushing guillotine. Rubber roller with roller distance setting mechanism. Toothed roller, assembled by series of toothed disks and spacers. Comb scraper for toothed roller. Sorting blade for total separation of the stones from the mash. Rollers are driven by geared motor and chain transmission.

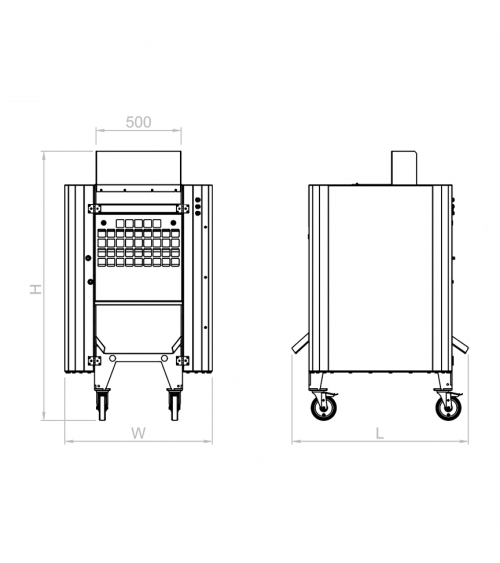

| REFERENCE | PRODUCTION | DIMENSIONS | INSTALLED POWER |

WEIGHT |

| ROT500 | Up to 3,000 kg/hour | 1,050 x 880 x h. 1,610 mm | 1.5 kW | 430 kg |