Deaerator

When processing fruit juices and purees, entrapped gasses, particularly oxygen in the product after packing can seriously harm its quality. Dearator is used in order to remove the incorporated and dissolved air in the product and consequently extend shelf life, and this also greatly enhances product stability.

The deaeration is performed by vacuum, in order to avoid oxidation. Product is fed through an inlet nozzle, which creates an even product layer on the inner container wall. The flowing film enables short diffusion paths for the gas bubbles coming from the product. Vacuum pressure is adjusted to the infeed temperature and product properties.

Deaeration can be performed in cold or hot situation. In hot situation vapors with dissolved aromas are sucked from product. The aromatic vapors can be condensed and newly incorporated directly into the product by means of an aroma recovery device.

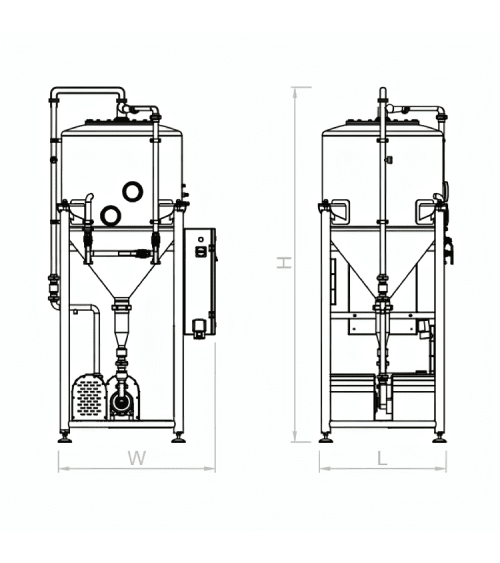

Stainless steel frame mounted on leveling feet, with vacuum chamber. Inlet nozzle for even spraying the product on the wall of the chamber. Vacuum unit with liquid ring vacuum pump. Product outlet, mono-crew pump. CIP nozzles in the chamber. Aroma recovery unit, with CIP system.

| REFERENCE | CAPACITY | DIMENSIONS | INSTALLED POWER |

WEIGHT |

| D1000 | Up to 1,000 litres/hour | 890 x 1,100 x h. 2,400 mm | 3 kW | 190 kg |