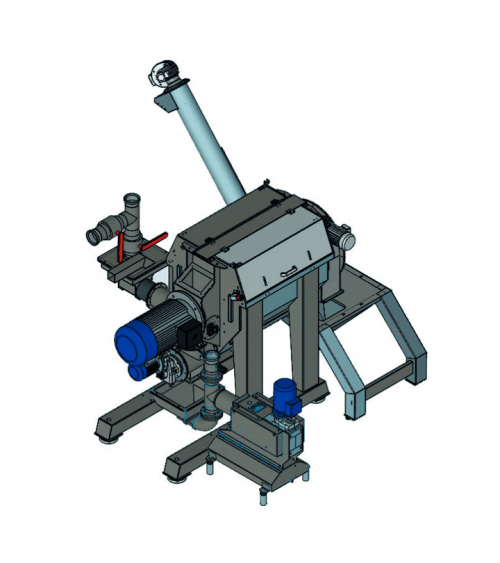

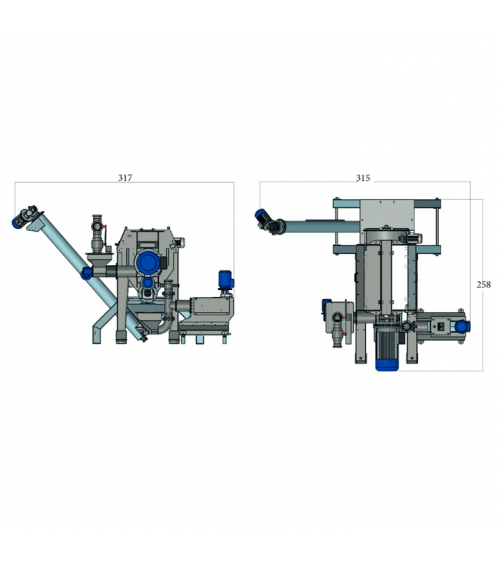

Depitting machine SN 1000 to 4000

SN pulp bone separator with pump and production from 1,000 kg/hour up to 4,000 kg/hour. The machine consists of a loading hopper. It has a separating drum with a 3-blade agitator that centrifugates the product and also separates the bone from the wet pulp (minimum 50%, no water can be added).

A polisher keeps the drum clean and an auger feeds the elliptical piston pump that carries the paste to the container. The recovered stone is 13 to 18% of the olives used. The installed power can be 14 kW, 15 kW, 18 kW, 22 kW or 27 kW, depending on the model. This SN pulp stone separator has a three-phase current, 380 V.

| REFERENCE | PRODUCTION | POWER | DIMENSIONS |

| SN 1000 |

1,000 kg/hour | 14 kW | 3,170 x 2,580 x h. 3,150 mm |

| SN 1500 |

1,500 kg/hour | 15 kW | 3,170 x 2,580 x h. 3,150 mm |

| SN 2000 |

2,000 kg/hour | 18 kW | 3,170 x 2,580 x h. 3,150 mm |

| SN 3000 |

3,000 kg/hour | 22 kW | 3,170 x 2,580 x h. 3,150 mm |

| SN 4000 |

4,000 kg/hour | 27 kW | 3,170 x 2,580 x h. 3,150 mm |