Flanged butterfly valve with triple eccentricity − Tri Lok

Flanged butterfly valve with triple eccentricity − Tri Lok. Premier isolation valve well-suited for operation from vacuum to high-pressure applications and ideally suited for applications requiring absolute zero leakage. Compared to gate, globe or ball valves of the same size and pressure class, Tri Lok provides space and weight savings while minimizing installation and maintenance costs. Size range: DN80 a 1200. Working temperature: -196ºC +450ºC.

Tri Lok’s, non-rubbing, metal-to-metal seal delivers zero leakage with minimal torque and is certified fire-safe. The seal ring ensures uniform peripheral sealing with the seat, achieving full shutoff regardless of flow direction. Tri Lok offers a solid metal seal ring designed for high temperature and severe applications, ensuring dependable sealing performance throughout the full pressure and temperature range.

Bray Tri Lok is the only valve in its class with a splined disc/stem connection. The Tri Lok connection allows axial movement of the disc independent of the stem, keeping the seal ring and seat in position and unaffected by temperature fluctuations and pressure effects on the stem. This design prevents the typical misalignment problems of rigidly attached discs and stems to offer maximum strength. Close tolerance engagement between the disc and stem minimizes hysteresis.

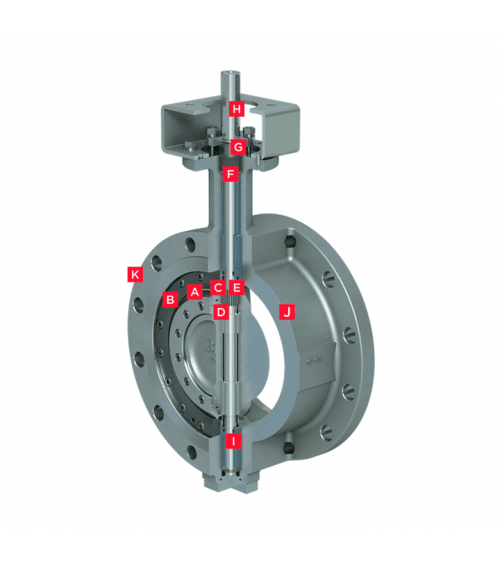

A. Field-replaceable seat & seal system: the fully field-replaceable seat & seal extends overall life, minimizes downtime, and reduces the need for costly off-site repairs or total replacement.

B. Enhanced seat hardness: eliminates risk of seat/seal galling, offering superior performance, durability, and abrasion resistance compared to other materials.

C. Metal-to-metal sealing: Tri Lok’s non-rubbing, metal-to-metal sealing system is inherently firesafe and fire-tested, while meeting zero-leakage requirements for many critical applications.

D. Seal ring: offers a flexible design and wide range of materials to provide torque-loaded sealing with zero-leakage. (Optional solid seal ring available.)

E. Splined disc-to-stem connection: the strong and reliable connection allows for axial movement of the stem independent of the disc, to protect the disc/stem connection from temperature fluctuations and pressure effects. This connection prevents typical misalignment problems of rigidly attached discs and stems, minimizes hysteresis, eliminates external connections & associated hardware, and allows for easy assembly & disassembly.

F. Adjustable stem packing: fully-adjustable, field-replaceable stem seal system is certified to international fugitive emission standards.

G. Robust blowout-proof stem: one-piece stem features blowout prevention ring located outside of the pressure boundary, as well as redundant blowout prevention mechanisms fully conforming to API 609 and safety requirements.

H. Indexed stem: provides positive visual indication of disc/seal ring position after installation.

I. Elongated stem bearings: hardened bearings provide maximum stem support.

J. Increased body wall thickness: in accordance with API 600, provides greater corrosion allowance.

K. SIL 3 capable: the Tri Lok valve is SIL 3 capable, while also offered as one of Bray’s many automated packages that meet various SIL requirements.