McCannalok high performance butterfly valve

The McCannalok high performance butterfly valve (also known as a double offset butterfly valve) features an innovative design that offers rugged reliability and extremely easy maintenance in the field. Independent and internal tests prove the Series McCannalok valve's superior service life capability, with zero leakage shutoff. Size range: 2" to 66". Temperature range: -52ºC to 260ºC.

The McCannalok valve’s unique, patented design received Chemical Processing’s Vaaler Award for Best Product shortly after it was introduced. The simple, innovative design offers rugged reliability and extremely easy maintenance in the field.

Independent and internal tests have proven superior service life capability with zero leakage shutoff through over 100,000 cycles. Series 40 Bray/McCannalok valves can be automated inexpensively with any of Bray’s pneumatic and electric actuators. The McCannalok high performance valve delivers the highest quality and highest value available for your requirements. After a test of over 100,000 cycles at 720 psi (49.6 Bar), the seat remained in excellent condition, continuing to provide a bi-directional zero leakage seal. Even after more than 878,000 cycles at 2 psi (0.1 Bar), the McCannalok high performance valve still sealed zero leakage in both directions.

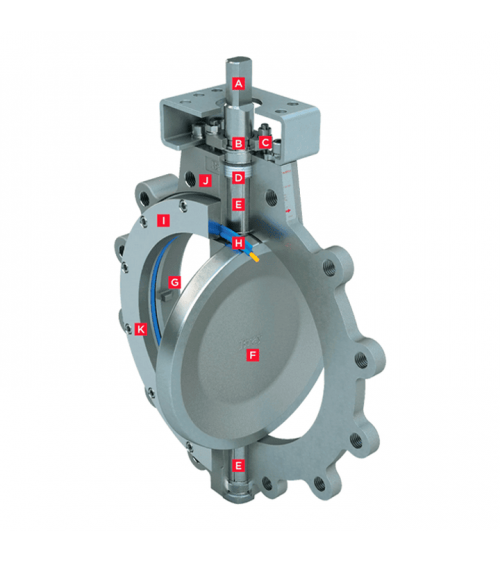

A. Stem design: high-strength, one-piece stem design is standardized for interchangeability of Bray actuators.

B. Blowout-proof stem: the stem retention design does not rely on actuation components to prevent stem blowout.

C. Adjustable stem packing: easy access allows simple quarter-turn field adjustments without actuator removal.

D. Stem seal packing: PTFE packing rings with carbon fiber anti-extrusion ring provides constant compression for a positive seal around the stem. Options are available for high temperature, high cycle and firesafe applications.

E. Stem bearings: top and bottom bearings securely support the stem, provide excellent corrosion resistance, and minimize deflection from high temperatures and mechanical loading forces.

F. Disc: the disc is engineered to maximize flow and minimize resistance for optimal flow rates.

G. Internal over-travel stop: designed to minimize possible seat damage — extending the service life of the seat.

H. Bidirectional resilient seat: provides bidirectional zero-leakage sealing while isolating the energizer from line media.

I. Full-faced seat retainer: cap screws located outside sealing area are protected from corrosion while allowing simple seat replacement.

J. Body: extended neck allows access to stem packing adjustments and actuator mounting when valve is fully insulated.

K. Dead-end service: Lug and double-flanged bodies are full rated for bidirectional dead-end service.

Series 40/41/4A (up to 19.6 bar):

| MODEL | BODY | RESILIENT SEATED | FIRESAFE | METAL SEATED |

| 40 | Wafer | 2" to 66" | 2" to 48" | 2 1/2" to 36" |

| 41 | Lug | 2" to 66" | 2" to 48" | 2 1/2" to 36" |

| 4A | Doble flanged | 2" to 54" | 2" to 48" | 2 1/2" to 36" |

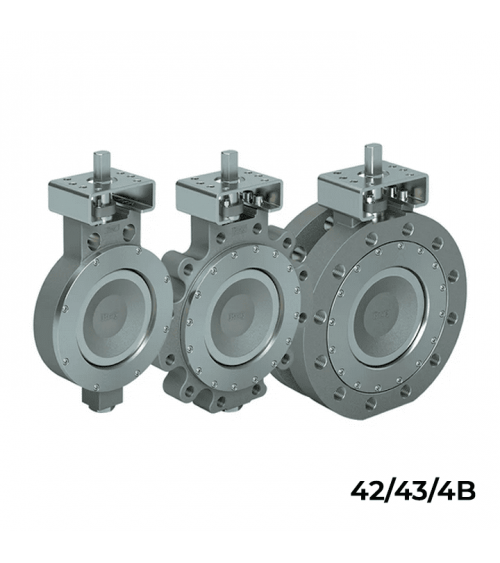

Series 42/43/4B (up to 51 bar):

| MODEL | BODY | RESILIENT SEATED | FIRESAFE | METAL SEATED |

| 42 | Wafer | 2" to 36" | 2" to 36" | 2 1/2" to 30" |

| 43 | Lug | 2" to 54" | 2" to 36" | 2 1/2" to 30" |

| 4B | Doble flanged | 3" to 42" | 2" to 36" | 2 1/2" to 30" |

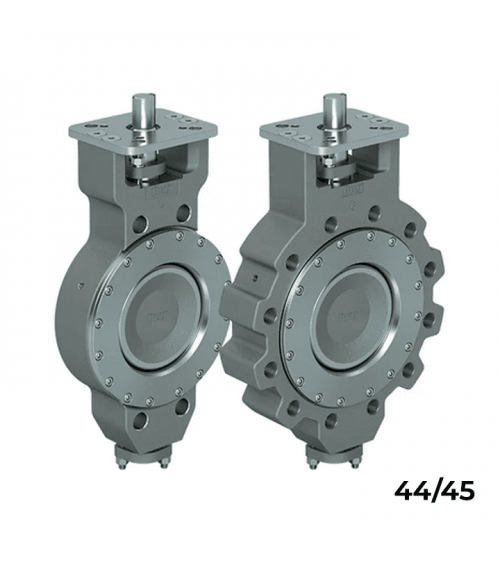

Series 44/45 (up to 100 bar):

| MODEL | BODY | RESILIENT SEATED | FIRESAFE | METAL SEATED |

| 44 | Wafer | 3" to 24" | 3" to 24" | 3" to 12" |

| 45 | Lug | 3" to 36" | 3" to 36" | 4" to 12" |