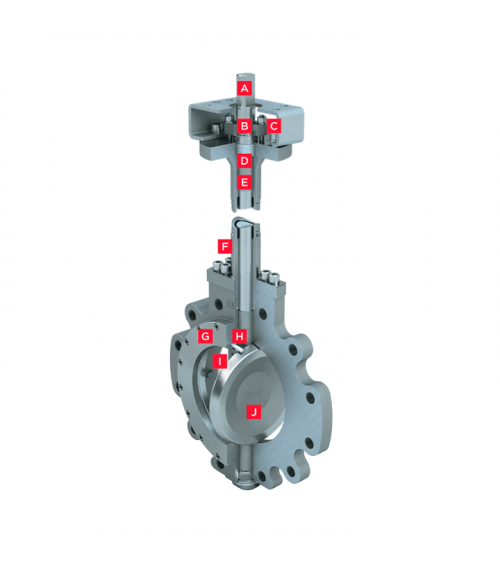

McCannalok high performance Cryogenic Lug type butterfly valve

The McCannalok Cryogenic high performance Lug butterfly valve provides industry leading cryogenic sealing technology and performance while being produced to the highest quality standards. The valve is designed to handle the most difficult medias in today’s industrial environments — liquid oxygen, liquid natural gas, and other cryogenic liquids. Size range: DN80 a 600. Working temperature: -196ºC +121ºC. Available also in Wafer.

McCannalok cryogenic features:

- The advanced Polar® Seat provides strength, flexibility, and unparalleled performance at cryogenic temperatures.

- Industry leading leakage performance, with high cycle capability, at cryogenic temperatures.

- Material compatibility with liquid and gaseous oxygen, certified by third party testing laboratory.

- One-piece, high-strength, low temperature impact resistant stem.

- Contoured disc to maximize flow.

A. Stem design: high-strength, one-piece stem design is standardized for interchangeability of Bray actuators.

B. Blowout-proof stem: the stem retention design does not rely on actuation components to prevent stem blowout. Designed to provide safe operation for cryogenic conditions.

C. Adjustable stem packing: easy access allows simple quarter-turn field adjustments without actuator removal.

D. Stem seal system: PTFE packing rings, compresssed by the packing gland, provide a positive seal around the stem. Certified compatibility with liquid and gaseous oxygen service (tested by third party).

E. Stem bearings: top and bottom bearings securely support the stem, provide excellent corrosion resistance, and minimize deflection from mechanical loading forces.

F. Bolted bonnet: connection prevents internal stress during valve cool-down. Extended neck protects stem packing from extreme temperatures, and allows access for stem packing adjustments and actuator mounting.

G. Full-faced seat retainer: utilizes cap screws located outside the flange gasket sealing area — improving flange gasket sealing and allowing simple seat replacement.

H. Polar seat: jacket and energizer maintain consistent sealing performance during process thermal cycling and extend valve cycle life by reducing seat wear. Provides sealing at temperatures as low as -320°F (-196°C).

I. Internal travel stop: minimizes possible seat damage and extends the service life of the seat.

J. Disc: the disc is engineered to maximize flow and minimize resistance, for optimal Cv / Kv values.