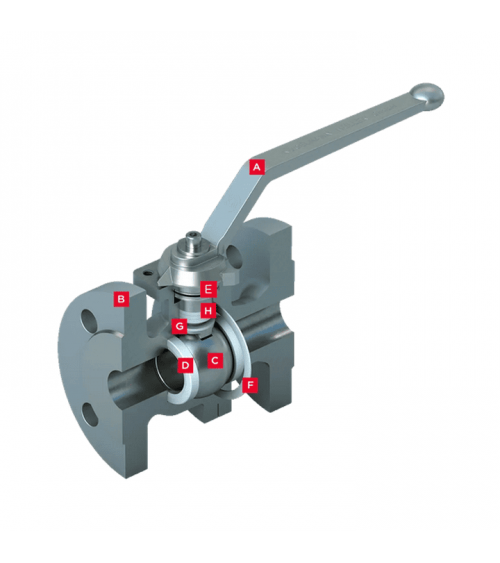

Flanged ball valve − series KM 20/21

Kugelhahn Müller flanged ball valves are engineered to meet stringent Namur NE 167 requirements for industrial valves for the chemical and petrochemical industry where safety, durability, and long service life are paramount. Available in various configurations and trims, Kugelhahn Müller flanged ball valves are ideal for use in a wide range of media, including acids, alkalis, corrosive chemicals, gases, hydrogen, and oxygen service, as well as, food and beverage (FDA-compliant), pharmaceuticals, water, and wastewater treatment industries where corrosion resistance and robust construction translate into long service life with minimal maintenance.

Manufactured under stringent quality standards, Kugelhahn Müller flanged ball valves feature a robust blowout-proof stem design with an adjustable live-loaded PTFE stem packing and an optional O-Ring sealing systems, designed to minimize fugitive emissions. This feature is particularly important in high-pressure applications, where enhanced safety is paramount. Size range: DN 15 to 200. Maximum allowable operating pressure: 40 bar. Temperature range: -60ºC to 200ºC. Body materials: carbon steel (EN 1.0619) or stainless steel (EN 1.4408).

Optional trims and configurations are available for a wide range of industrial flanged ball valve applications including exotic alloys, ISO 10497 fire-safe designs, antistatic capabilities to prevent static discharge, high-temperature capabilities, graphite seals, v-ball control valve trims and steam heat-jacketed versions. A comprehensive range of accessories is also available, enabling valve customization to meet bespoke customer requirements.

Kugelhahn Müller’s reputation for reliability, safety, ease of maintenance, and an industry-leading warranty ensures that our flanged ball valves are the perfect choice for demanding industries requiring long-lasting valve solutions.

A. Hand lever: stainless steel lockable hand lever with a position indicator.

B. Body: robust two-piece body design suitable for heavy-duty applications in multiple industries. A wide range of flange connections are available.

C. Ball: floating full bore design made of polished stainless steel.

D. Seat: seat design ensures bidirectional zero-leakage sealing under all pressure and temperature conditions.

E. Stem: heavy-duty, blowout-proof stem with “Double D” connection according to ISO 5211 for mounting of various hand levers, adapters, actuators and stem extensions.

F. Body seals: chambered body seal design to ensure outstanding sealing integrity.

G. Stem packing: designed with high integrity stem packing arrangement that combines a self-adjusting primary and secondary seal in order to ensure consistent torque and highest possible tightness according to ISO 15848-1.

H. PTFE packing: the PTFE sealing system features a preloaded Belleville spring design with the benefit of optional readjustement.